Application Notes

We have summarised typical applications of our technology at customers and partners in the following list of Application Note documents.

PAT Approaches for Biorefineries

#308, MIR / Raman / NMR

Key process steps for the valorization of Biomass in a biorefinery can be elucidated, monitored and optimized with spectroscopic PAT tools: infrared for chemical digestion, NMR and Raman for the generation of platform intermediates, and Raman for the downstream work-up. In all cases, spectral Hard Modeling allows the spectral analysis of the process mixtures for precise quantification.

Monitoring the degree of hydrogenation

#804, Raman

In this case study, the degree of hydrogenation of liquid organic hydrogen carriers (LOHC) is analyzed with a novel Raman technology from Optoquant. Real process samples containing benzyl toluene, dibenzyl toluene, and other LOHCs are analyzed by the use of a ratiometric PEAXACT model.

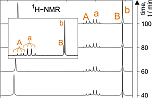

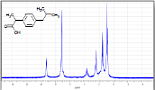

Automated quantitative NMR analysis

#803, NMR

Quantitative nuclear magnetic resonance (qNMR) is used within the quality control of Silanes. PEAXACT methods are used to analyze complex overlapping signals within the TopSpin/IconNMR environment. Therefore, our PEAXACT AppServer was embedded into the automated qNMR workflow.

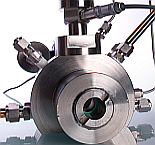

Urea process monitoring

#108, Raman

Monitoring the production of urea from CO2 and ammonia bears multiple challenges in an industrial environment: high pressure, high corrosivity, very sensitive reaction equilibria, and the inaccessibility of representative process samples. It needs Process Raman and intelligent quantitative modelling to solve it!

Quality control of Silanes

#802, NMR

Silanes are highly versatile materials for a multitude of applications. Product properties are adjusted by blending additives or stabilizers, according to the field of application, which needs precise release control. Low-field nuclear magnetic resonance spectroscopy (LF-NMR) is the key to success here, combined with spectral analysis using spectral Hard Modeling.

PIONA and detailed analysis of hydrocarbons

#107, Raman

Hydrocarbon streams in Petrochemical processes require composition analysis, both P-I-O-N-A contents (n-/iso-/cyclo-paraffins, olefins, aromatics) and detail single component analysis. Real-time access to this information is given through Process Raman technology. Intelligent calibration approaches reduce the effort for multi-parameter calibrations dramatically.

Real-time rubber structure elucidation with Raman

#203, Raman

The generation of synthetic rubber from dienes and olefins is monitored in real-time with inline Raman spectroscopy, allowing to track the insertion type of the monomers into the polymer immediately and in detail. Laborious and time-consuming offline analysis can be substituted, speeding up recipe optimisation tremendously.

Chemometrics for Bioprocesses

#305, Raman/MIR/...

Does spectral analysis always need to rely on the same method/approach? Taking bioprocesses with their abundancy of process parameters typically modelled by multivariate statistics only, we show how to use the entire chemometrics toolbox more efficiently with PEAXACT.

Process Analysis with online NMR spectroscopy

#104, NMR

Benchtop NMR equipment in continuous flow mode is utilised as an online process analyser for an esterification. Indirect Hard Modeling (IHM) optimises the synchronous evaluation of 1H and 19F spectra.

Estimating pure component spectra with HMFA

#905, MIR

The multi-step synthesis sequence of a fine chemical is elucidated by applying Hard Modeling Factor Analysis (HMFA) to MIR spectra measured inline. The estimated pure component spectra are validated through mixtures samples prepared in the lab and thus allow to develop set up the reaction network.

Innovative polymer production with CO2

#202, MIR

CO2 is converted with epoxides into innovative polyethercarbonates. The formation of carbonate and polyether moieties is observed inline with ATR-MIR spectroscopy under harsh conditions. Indirect Hard Modeling (IHM) allows bottom-up spectral modelling for quantification.

Identification of Pharma ingredients

#603, MIR+Raman

The robustness of a Raman and mid-IR based substance identification has been proved with the help of a discriminant analysis approach. Spectra of typical Pharma ingredients have been recorded under systematically varied conditions. Classification models were trained and validated with independent material samples.

Production of bio-based platform chemicals

# 304, Raman

Platform chemicals based on renewable feedstocks typically require the hydrogenation of plant-based carbohydrates (sugars, cellulose, …) in pressurised reactors before they undergo consecutive reactions. These conversions are well observable with fibre-optical inline Raman spectroscopy.

Monitoring an API crystallization online with ATR-MIR spectroscopy

#402, MIR

The development of an API crystallization process is monitored with ATR-MIR spectroscopy throughout lab and pilot plant scale. Model transfer is significantly facilitated through the use of Indirect Hard Modeling.

Raman Monitoring of Biogas Production from industrial sewage sludge

#303, Raman

The generation of bio-methane in a converter of industrial sewage sludge is monitored by gas-phase Raman spectroscopy. Measurements are performed directly in the product gas stream. The influence of process parameter changes is well reflected in the predicted methane profiles.

Continuous aqueous solution polymerisation

#201, MIR

Acrylic acid and related monomers are continuously polymerised in aqueous solution. For MIR spectroscopic monitoring, probes are installed along the entire reactor length. Indirect Hard Modeling is required to separate monomer and polymer contributions to the spectra.

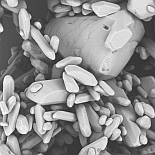

Raman Monitoring of Fermentations for Organic Acids Production

#302, Raman

Substrate and product content in an industrial bio-process are monitored by Raman spectroscopy. Time resolution is improved dramatically compared to offline analysis. The immediate access to the process performance is capable of online process control.

Quantitative analysis of carotenoids in food samples with UV-VIS spectroscopy

#601, UV-VIS

Carotenoid contents of various food samples are determined with UV spectroscopy. Though similar in structure, an Indirect Hard Modeling analysis is capable of separating the overlapping spectral contributions of the different components.

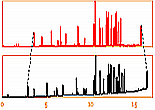

Chromatogram Classification with PEAXACT Chrom

#903, GC

Gas chromatograms are classified before quantitative analysis. A model-based unsupervised approval procedure in PEAXACT Chrom identifies typical irregularities like missing or additional peaks, retention time shifts, etc. Batch approval times are significantly reduced.

Benchtop NMR for quantitative analysis

#602, NMR

Benchtop NMR spectrometers nowadays generate spectra of such a high quality that quantitative analyses of mixtures are significantly facilitated. In case of very similar mixture components (here sugars), Indirect Hard Modeling (IHM) is a valuable analysis method for the deconvolution of mixture spectra.

Distillation monitoring with fibre-optic MIR spectroscopy

#401, MIR

A glass-made tray column is equipped with a 4-sensor MIR spectroscopic system. Concentrations are not only measured in sump and head product stream, but also on the trays. The Indirect Hard Modeling analysis restricts the required reference measurements to ambient temperature.

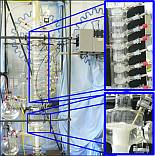

Spectroscopic Monitoring of Flow Chemistry

#102, MIR

A continuous esterification is performed in micro-structured reactors and monitored with miniaturised MIR spectroscopy. Measured spectra are immediately analysed with PEAXACT. Predictions allow for real-time observation or control of the process.

Water Vapour compensation through Indirect Hard Modeling

#902, MIR

Water vapour in MIR spectra is compensated through an Indirect Hard Modeling approach. Treating water vapour as a regular mixture component allows to account for variations in the overall content. The main component profiles emerge free of interference.

Inline Monitoring of Fermentations for Organic Acids Production

#301, MIR

MIR spectroscopy is applied for process monitoring in a pilot-scale fermentation of sugars. Thanks to an Indirect Hard Modeling approach, the water spectrum is accounted for in the analysis step. Online substrate content prediction can act as a shut-off criterion for the process.

Quantifying molecular interactions through Indirect Hard Modeling

#103, MIR

The influence of water traces on the properties of Ionic Liquids is assessed by MIR spectroscopy. Spectra are analysed with the Indirect Hard Modeling method. Resulting peak parameters, e.g. peak shifts, are used for quantitative determination of mixture physics.