Analyzer App Examples

We picked a few Analyzer App examples - each one based on a specific sensor - for different industries, applications, and process quantities. For more configurations see the product overview.

Polymerization Analyzer App

Parameters: residual monomer, n/iso ratio, tacticity

Technology: Raman, MIR

Polymerisations are the most voluminous processes in the chemical industries. Besides the traditional bulk polymers like PE, there are many specialised polymers for specific applications. Raman spectroscopy is the method of choice when it comes to olefin polymerisations.

Polymerisations in homogeneous phase can often be monitored with MIR spectroscopy since they transform functionalised monomers (e.g. polyesters, polyamides or polyurethanes).

Crystallization Analyzer App

Parameters: mother liquor composition, particle content, polymorph ratio

Technology: Raman, MIR, NIR

Producing particles out of super-saturated solutions typically requires careful control of the process parameters (temperature, stirrer speed etc.). Beyond that, controlling the nature of the particles and the composition of the mother liquor allows to ensure the successful growth of crystals.

Raman spectroscopy is an appropriate technique for the simultaneous monitoring of mother liquor and growing crystals, depending on the selection of the optical probe.

In return, mid-infrared (MIR) spectroscopy using the Attenuated Total Reflectance (ATR) mode is the method of choice for monitoring the mother liquor only, without interference of the crystals.

Aromatics Analyzer App

Parameters: BTEX content (benzene etc.), PAH (tars etc.)

Technology: Raman, UV-VIS

Aromatics are among the most valuable commodities in chemistry, but typically appear in groups of (regio-)isomers. With similar functional groups, but different structure patterns, their distinction is well achieved with Raman spectroscopy, e.g. in separation processes of o-, m- and p-xylene.

Fermentation Analyzer App

Parameters: metabolite content, biomass content, suspended matter

Technology: Raman, MIR, NIR, fluorescence

Industrial fermentation is one of the most successful emerging process technologies. Once a promising biocatalyst (enzyme, organism, …) is identified, it will typically deliver a high-value product out of simple nutrients like sugar, lignin, or other biomass. The transformation is typically slow, but of a high specificity, however some undesired metabolites allow to identify aberrations of the process at an early stage.

Despite the success of near-IR based monitoring solutions that typically require extremely large training data sets, more specific methods like Raman or mid-IR spectroscopy can be applied that are less sensitive to process changes.

Distillation Analyzer App

Parameters: mixture composition, purity

Technology: MIR, UV-VIS, Raman

Compared to sampling-based methods like chromatography, all inline methods – Raman, infrared, UV-Vis spectroscopy – are highly beneficial for distillations, extractions and related processes. Since they do not need sampling, thermodynamic equilibria are not affected. With the intrinsic temperature gradients, these processes bear a specific challenge for spectroscopy: spectra are typically temperature dependent. Intelligent ways of data analysis will however avoid excessive calibration works.

Many purification-type distillations will work out fine with UV-Vis spectroscopy, isomer separations are preferably served with Raman, many others with infrared spectroscopy.

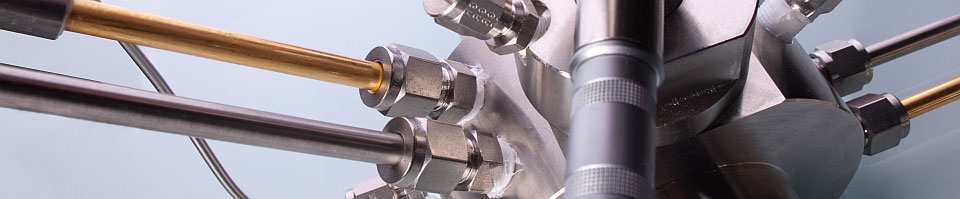

High Pressure Analyzer App

Parameters: conversion, H2/CO excess, adsorbate density

Technology: MIR, Raman

High Pressure chemistry is one of the fundamental technologies in the Process Industries. In early process development, being close to the targeted process conditions – pressure, temperature, etc. – is crucial for successful optimisation. Small-scale high pressure setups benefit strongly from sampling-free inline analytical techniques like spectroscopy with fibre-optic probes.

For many applications, including non-reactive processes like selective absorption, Raman and mid-infrared analysers are very valuable options.

Surface Analyzer App

Parameters: Surface structure, adsorbates, coating quality

Technology: Raman, NIR

Analysing solid surfaces that change composition, structure or any other property, always requires the careful selection of a representative measurement spot. The selected material is then either monitored throughout the process (e.g. in a catalyst fixed bed), or the solid material is moved through the measurement spot, e.g. in a coater, extruder, slurry. Thanks to the well-defined excitation focus of online probes, Raman spectroscopy is well-established for selective monitoring of surfaces.

Olefin Analyzer App

Parameters: ethylene content, C4 isomers ratio, bromine/iodine index

Technology: Raman, UV-VIS

Olefins are the foundation of chemical value chains and are produced by steam cracking of crude hydrocarbon mixtures. Whereas ethylene and propylene are comparably easy to separate and to analyse in the raw mixtures, the distinction of higher olefin isomers is challenging. Nevertheless, Raman spectroscopy is capable of distinguishing between the isomers and is a valuable tool for applications both in liquid or gaseous mixtures.

Hydrogenation Analyzer App

Parameters: residual hydrogen and olefin, bromine/iodine index

Technology: Raman, MIR

Hydrogenations of complex substrates like APIs or specialty chemicals are adding high value to the material. High requirements to selectivity, be it chemo-, region- or stereoselectivity – increase the need for reliable online monitoring as a control tool for the process performance.

Mid-IR spectroscopy is typically preferred if ketones, aldehydes, NOx or SOx groups need to be hydrogenated. Raman spectroscopy is beneficial e.g. for selective olefin hydrogenation – and under some conditions it will analyse also the dissolved hydrogen!

Polymorphs Analyzer App

Parameters: polymorph ratio, transmodifications

Technology: Raman

Some crystalline solids come in different crystal (lattice) structures. Especially in Pharma production only one of these polymorphs is desired, since the others may show no or even negative effects when applied to the patient. In many cases, Raman spectroscopy is capable of distinguishing between the polymorphs and thus allows for a reliable process control.

Continuous Flow Analyzer App

Parameters: substrate/product concentration, conversion

Technology: MIR, Raman

Emerging reactor technologies like small-scale flow reactors put specific requirements to process analytics. In contrast to some of the available solutions e.g. for MIR spectroscopy, we highly recommend not to adapt the process to the analyser, but to use tailored analytical equipment minimising the impact on the process!

Coupling a miniaturised fibre-optical MIR probe into an optimised flow cell design has been a powerful tool for process monitoring and equipment characterisation (residence time behaviour etc.).

Aqueous Analyzer App

Parameters: Product + substrate concentration, by-products

Technology: Raman, MIR

Aqueous media are typically analysed with Raman spectroscopy, due to the fact that water shows basically no Raman signal. One needs to be aware of fluorescence in biogenic aqueous media.

However, despite the widespread prejudice, there is high potential also for the application of infrared (mid-IR, sometimes NIR) methods. High concentrations are certainly preferred, but intelligent methods for data analysis may help you go down into concentration levels below 1%.

Color Analyzer App

Parameters: Colour Index, colour spectrum

Technology: UV-VIS, fluorescence

Colour is a very common parameter indicating reaction progress or product quality. Typically, colour indices are determined offline through simple colorimetric test systems, or online through single-wavelength photometric devices. The most comprehensive colour information is accessible with UV-Vis spectrometers, probing the process stream with transmission cells/probes or ATR probes.